Treatment of liquid manure and digestate

With the change of the EU fertilizer regulation, the spreading and use of agricultural fertilizers is further limited. Farmers and biogas plant operators are often left with only costly temporary storage and expensive external disposal since the processes currently available on the market do not meet the requirements and involve high operating costs. Yet for a long time, there have been various technically mature (and therefore already cost-optimized) wastewater treatment processes, which can be used – and are already in use internationally – for the treatment of liquid manure and digestate. The right combination of those technologies makes it possible to find the best solution for each site, whether it includes the reduction of storage volume or the recovery of nutrients.

Membrane processes (nanofiltration / reverse osmosis) are used for the separation of water and nutrients. The separated water is purified as much as necessary for reuse. The concentrate contains the dissolved nutrients, depending on the process combination NPK, NK or only K. Membrane plants have a significant advantage: they are delivered pre-assembled in containers and are very compact. Great importance must, however, been attached to the pre-treatment to protect the membrane stage. If the use of the agricultural fertilizer is only N-limited, the recovery of nitrogen in stripping plants as ammonium sulfate solution for fertilizing purposes might be an economic option

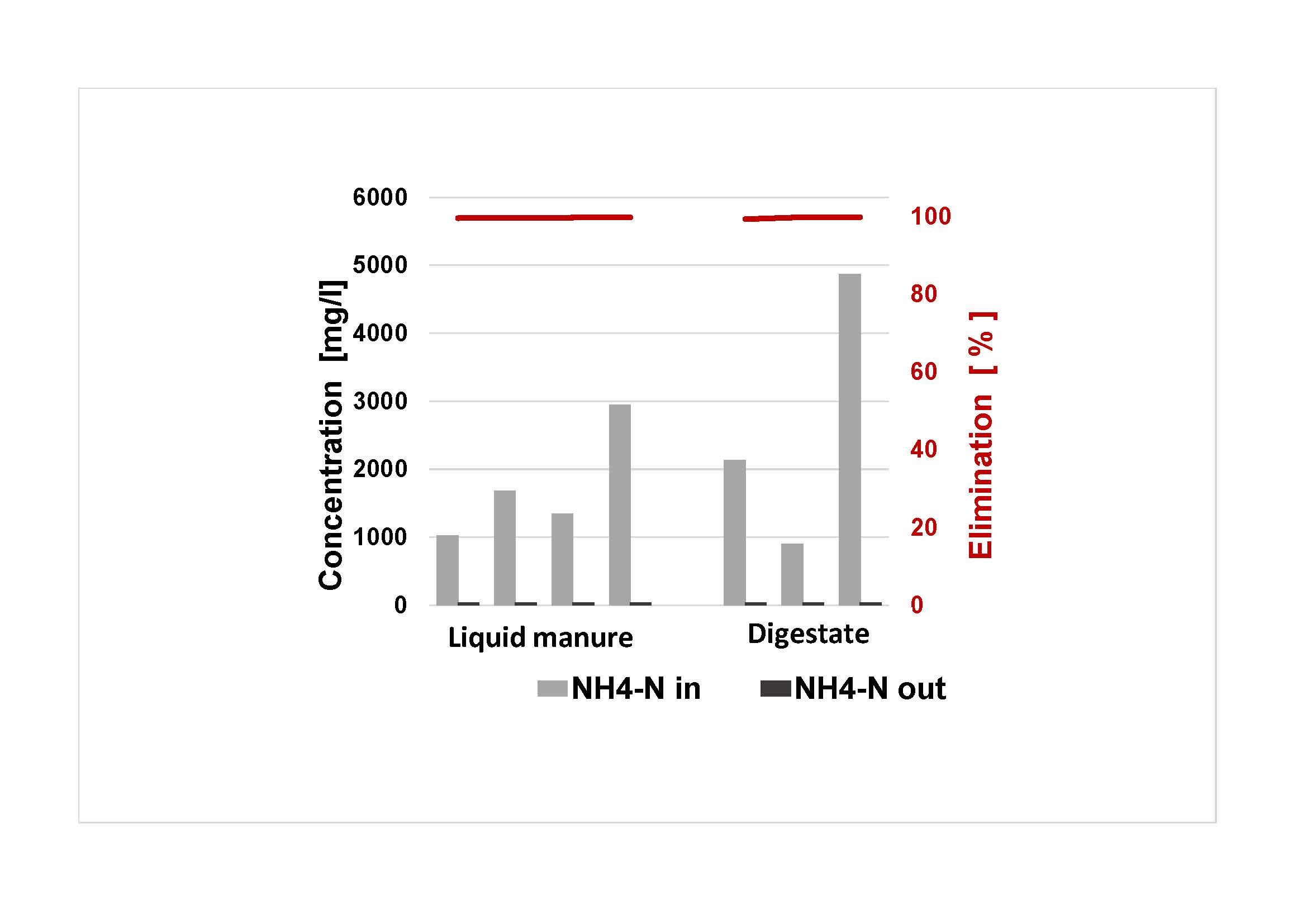

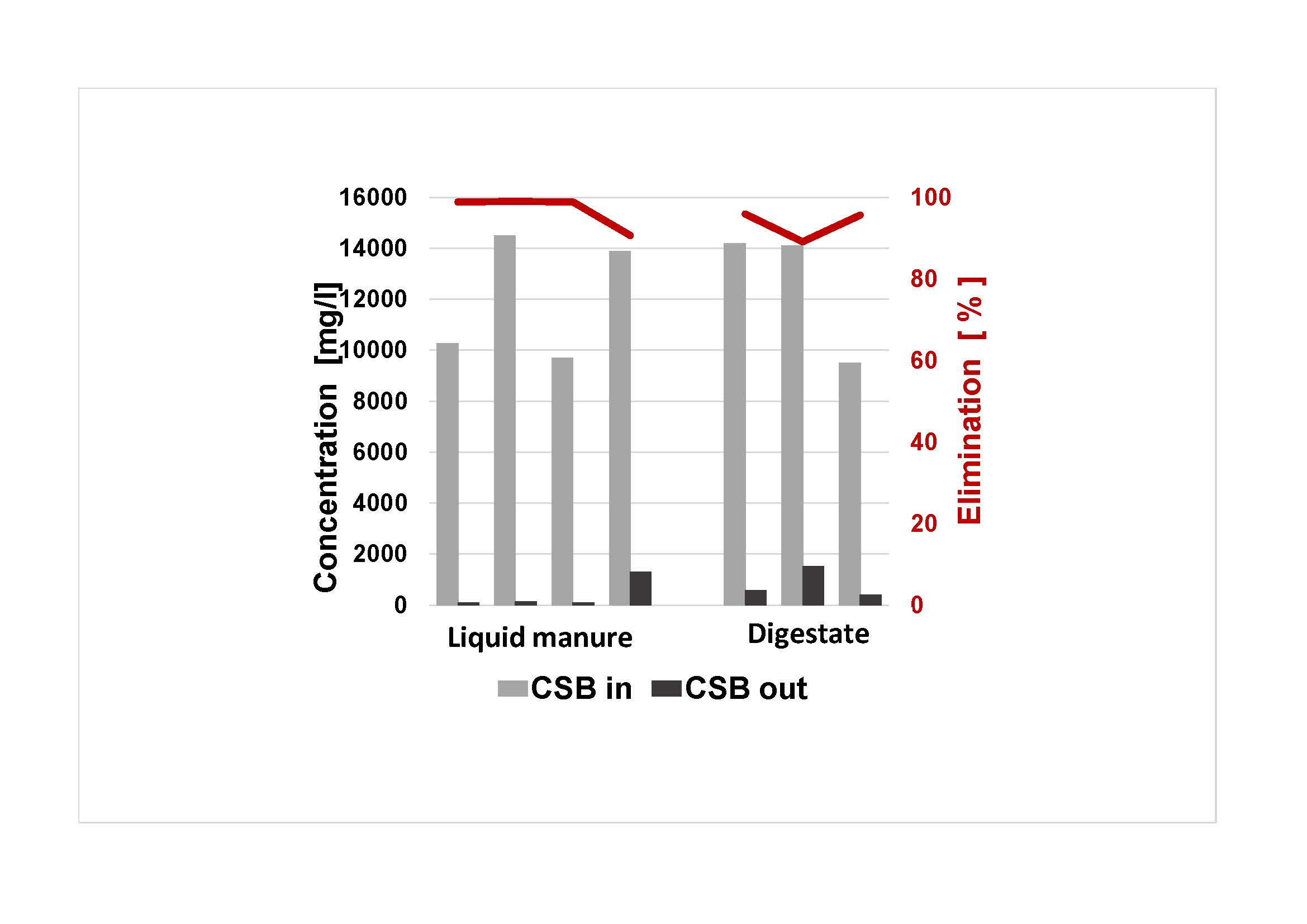

It happens more and more frequently that neither the concentration nor the recovery of nitrogen are expedient since there are no possible applications for the fertilizer concentrates. In this case, the biological treatment in Membrane BioReactors (MBR) is a true alternative. For decades, MBRs have been state-of-the-art in the treatment of landfill leachate and effluents from waste treatment. Since 2015, the MBR is also used for liquid manure and digestate. One of the MBR’s advantages is its flexibility: even in case of large differences in the concentrations of nitrogen and organic matter in the substrate, the complete elimination of nitrogen and the extensive elimination of organic matter and thus of the Norg fraction is reliably achieved (see figure 1).

The MBR is an indispensable element to achieve the water quality required for direct discharge. Direct discharge quality can only be obtained by combing different processes, each of which must reliably fulfill its task. Figure 2 shows that this is now feasible.

The MBR is an indispensable element to achieve the water quality required for direct discharge. Direct discharge quality can only be obtained by combing different processes, each of which must reliably fulfill its task. Figure 2 shows that this is now feasible.

Digestate |

after decanter |

after MBR |

after RO (1-pass) |

||||

TDS |

4.2 % |

TDS |

1.2 % |

TDS |

0.8 % |

TDS |

< 0.1 % |

Ntotal |

9,500 mg/l |

Ntotal |

5,700 mg/l |

Ntotal |

< 400 mg/l |

Ntotal |

< 25 mg/l |

NH4-N |

6,900 mg/l |

NH4-N |

4,900 mg/l |

NH4-N |

< 5 mg/l |

NH4-N |

< 1 mg/l |

Ptotal |

845 mg/l |

Ptotal |

285 mg/l |

Ptotal |

69 mg/l |

Ptotal |

< 1 mg/l |

Treatment of liquid manure and digestate - conclusion:

The combination of different, synchronized process technologies makes it possible to individually adapt the treatment of liquid manure and digestate. Concentration and nutrient recovery are just as feasible as full purification. All processes mentioned above are field-tested and can be quickly implemented.

Author:

Dr. Miriam Weissroth, Research & Product Development, WEHRLE Umwelt GmbH