Recycling System for the treatment & use of laundry wastewater

The proper and gradual recycling of water is becoming increasingly important, and not just since the focus on the water footprint is growing.

The proper and gradual recycling of water is becoming increasingly important, and not just since the focus on the water footprint is growing. For industrial companies, which always have to treat varying water volumes and/or high loads, reliable and efficient wastewater treatment is indispensable. Due to the rising costs of fresh water and the global water shortage, sustainable industrial companies, such as Kreuznacher Zentralwäscherei GmbH & Co. Mietwäsche KG, are more and more focusing on the sensible use of water and water recycling.

Like WEHRLE, Kreuznacher Zentralwäscherei GmbH & Co. Mietwäsche KG is a family-run company, which is active in the field of rental, laundering and processing of workwear for a wide range of industries and also committed to sustainability. Kreuznacher Zentralwäscherei is part of “dmw - die mietwäsche”, a network of family-owned companies from all over Germany that share the same sustainability goal. Since laundries produce large and highly loaded quantities of wastewater, the customer was looking for a solution for the treatment and use of the laundry wastewater.

Depending on the type of laundry and its origin, the effluents contain various oils, fats, halogens, salts, metals, minerals and surface-active substances. Together with WEHRLE, Kreuznacher Zentralwäscherei intends to create several internal water cycles in order to produce recyclable process water from the wastewater to be discharged. This enables the customer to comply with discharge limits, reduce costs for fresh water and wastewater, and thus significantly reduce its water footprint.

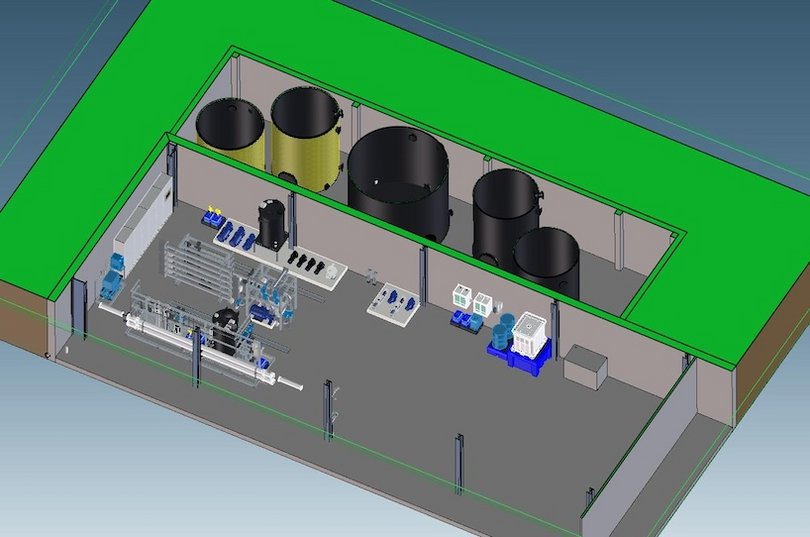

Within the project, WEHRLE is not only involved in the construction of the new wastewater treatment plant for the production expansion, but also in the planning and installation of a multi-stage water purification and water recycling system including energy generation. The technology used includes a high-performance BIOMEMBRAT® Membrane Bioreactor (MBR) and a Nanofiltration unit. The system eliminates organic pollutants, while simultaneously generating rinse washes for pre-washes. The Nanofiltration plant is a downstream separation stage that produces high-quality wash water.

The use of combined low-energy membrane processes makes it possible to significantly reduce electrical consumption. In addition to the savings in energy costs, the customer benefits from lower operating costs resulting from the increased efficiency of the plant and the reduced use of personnel.

Project Manager Manuel Leibrecht is delighted about the new reference for laundry wastewater: “Together with Kreuznacher Zentralwäscherei GmbH & Co Mietwäsche KG, we already installed a small pilot plant in the existing laundry 15 years ago. So we are very pleased to continue the successful cooperation and look forward to developing a reliable recycling system for the treatment and use of laundry wastewater for our customer.”

With the technology used, the laundry achieves a treatment capacity of approx. 65 m³ of wastewater per day as well as a reduction of COD from 2,000 mg/l in the inlet to less than 100 mg/l in the outlet of the Nanofiltration. The combination of the high-performance Membrane Bioreactor and the downstream Nanofiltration system ensures the successful recycling of a large part of the incoming wastewater – an important step for the sustainable use of the precious resource that is water.