About us

With tradition and courage to drive progress

160 years of family business from the Black Forest

As a family business with tradition, we combine the courage to drive progress with sustainability and reliability. Innovation and durability are not just characteristics of our products, they also reflect how we work at WEHRLE. The way we work and the know-how in the treatment of special waste and complex wastewater make us a driver of the green transformation. With our product world, we offer companies 360⁰ support in reducing their water footprint, resource recovery, resource conservation and sustainable energy production.

Reliable technology and energetic employees are crucial to achieving key social sustainability goals. In addition to in-depth know-how, we have a high degree of vertical integration, which allows us to fully support our customers in achieving their environmental goals in our local markets, beyond process engineering with design, production and assembly. Collaboration with leading research institutions helps us to always move forward and work together to develop suitable solutions for every task.

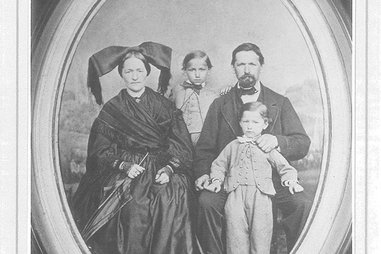

Heiner Steinberg (former CEO)

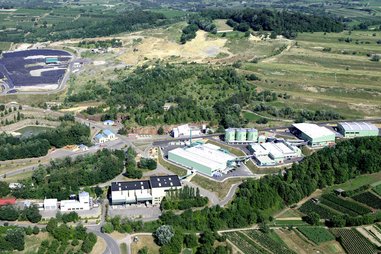

About the Emmendingen location

For over 150 years, the headquarters of our family business has been in the southwestern town of Emmendingen in the state of Baden-Württemberg. With a total of 6 subsidiaries and several cooperation partners worldwide, we are always a reliable contact for our customers.

The history of the company

With its technologies and systems, WEHRLE contributes to the green transformation. The Emmendingen-based family business supports other companies in reducing their water footprint and recovering resources through wastewater treatment and waste treatment technologies. Together with international sales partners, WEHRLE also contributes to improving living conditions, especially in developing and emerging countries, by treating landfill leachate. Decentralized combustion concepts for different fuels implement current topics of the Paris Climate Agreement such as a sustainable energy economy and the reduction of CO2 emissions.

In 2019, WEHRLE expanded the product portfolio to include grate combustion technology, which from now on complements the so-called fluidized bed combustion for the incineration of difficult waste and sewage sludge. With the expansion of its sustainability-oriented product range, WEHRLE is increasingly becoming a driving force behind the green transformation.

After ten years of research, piloting and testing, WEHRLE commissions the first MYT® plant, one of the most modern waste treatment technologies in the world for processing mixed household waste, in 2006. Since then, the plant at the Ringsheim site in the Ortenau district has ensured low waste disposal costs in the region.

In 1991, WEHRLE installed the world's first large-scale membrane bioreactor. Thanks to the high standard of purification, this enables the treated wastewater to be discharged back into nature, thus helping to conserve the valuable resource of water. Five years later, the world's first large-scale nanofiltration plant was built, also for wastewater treatment, and another ten years later, the first water recycling plant for the wastewater-free industry.

In the 1980s and 1990s, the existing portfolio was supplemented by process technologies for the treatment of complex and highly contaminated wastewater. Using membrane technology that was new at the time, WEHRLE built the first large-scale membrane bioreactors for landfills and industrial plants in the early 1990s.

In the 1970s, the Emmendingen-based company expanded its product focus to include technical engineering services. From this point on, WEHRLE has also been involved in designing and manufacturing high-pressure steam boiler systems for industrial cogeneration plants. From 1975 on, the product portfolio has included thermal waste treatment and energy generation from biomass.

Otto Wehrle, the son of the company founder, transforms the partnership he owns into the WEHRLE-WERK Aktiengesellschaft. Since then, 100% of the shares in the company have remained in the family of the company founder and are now held by a total of 3 generations (5th, 6th and 7th generation). Heiner Steinberg, the company's current CEO, comes from the 6th generation of the company and took over the management of WEHRLE-WERK AG in 2018.

Already in the 19th century, WEHRLE was making a name for itself internationally for good quality and solid construction work. Thanks to its good reputation in the field of brewery equipment and boilers for steam generation, the company grows rapidly and becomes a supplier to breweries all over the world. These include the 'Germania Brewery' in Tsing-tao, China, which was founded in 1903 and is now one of the ten largest breweries in the world. Further international projects were to follow in Dar es Salaam, Helsinki, Havana and Monaco, among others.

In 1860, Wilhelm Wehrle founded the "Mechanical workshop and boilermaking shop", laying the foundations for our company today, which was then located on the outskirts of the southern Baden district town of Emmendingen. The town grew around the factory, especially at the beginning of the 20th century, with and also thanks to WEHRLE. The central location and proximity to the population characterize the down-to-earth character of the family business.

You might also be interested in this

For over 160 years, WEHRLE has stood for reliable and sustainable service provision for its regional and international customers.

Sustainability

The most important success factor for our company is the reliable and quality-conscious work of our employees.

More about WEHRLE

We offer various career paths to support the Green Transformation!