WEHRLE-WERK AG

Bismarckstraße 1-11

D-79312 Emmendingen

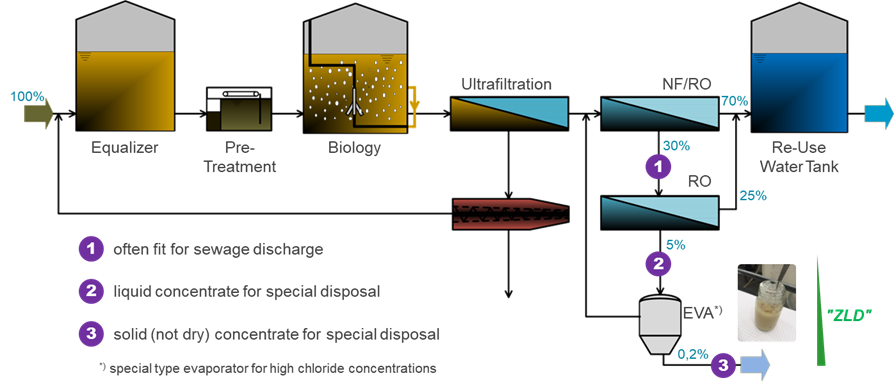

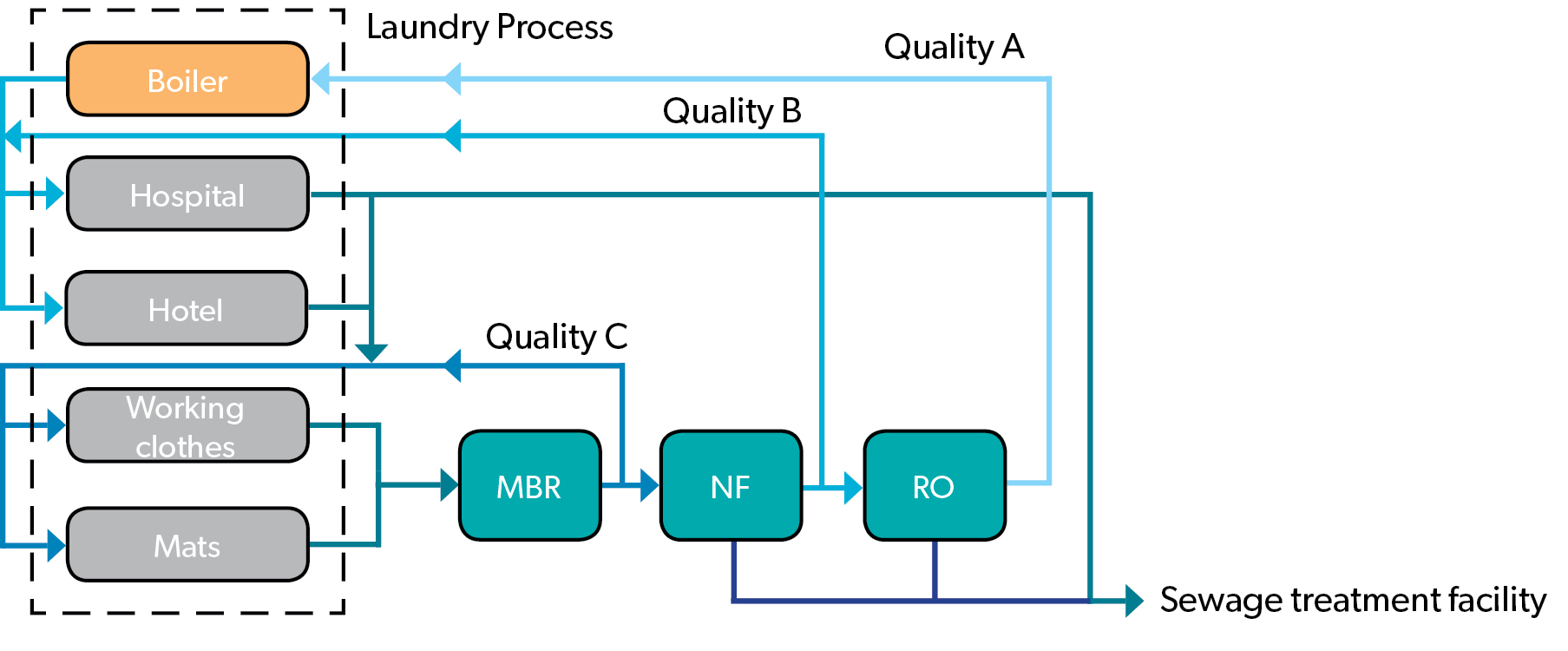

Water recycling and the reduction of the water footprint are important aspects of modern business management. In order to reduce fresh water costs, the produced wastewater may be treated for reuse, saving also heat and possibly water softening chemicals. Adapting the desired water quality to internal factory processes avoids an unnecessarily high treatment performance: Water-consuming processes are often less demanding, e.g. the pre-treatment of received goods. High process water qualities and an entire water recirculation (Zero Liquid Discharge / ZLD) are also possible.

The demand for Zero Liquid Discharge often comes with the company policy or in order to cope with unstable water supply. Zero Liquid Discharge aims at the maximum possible reuse of wastewater – but is it also economical? With a fraction of the costs, already large quantities of wastewater can be recycled. The last few percent water recovery increase the costs for such a system considerably. This is also because the treatment residues, the brine, need to be disposed of expensively. As a result, the reclaimed water may get more expensive than fresh water.

With an alternative solution with a combination of elimination and separation process steps, a better balance between ecology and economy can be achieved: The industrial wastewater can be treated to a level that still allows the concentrate to be discharged cheaply in the sewers. Typically the clean majority of the treated water can be used for internal processes.

In some companies, the concentrates or brines of the industrial effluent treatment plant carry valuable materials, washed out by the production process. Suitable process combinations can be used to recover such materials from the liquid and increase the resource efficiency of the production plant. See more under:

WEHRLE combines different technologies, such as biological processes or MBRs, membrane systems or evaporation, etc. to achieve the desired process water quality – as stand-alone solution for a direct treatment of the wastewater or as upgrade of an existing wastewater treatment plant.