WEHRLE-WERK AG

Bismarckstraße 1-11

D-79312 Emmendingen

Dead-End Ultrafiltration

A dead-end Ultrafiltration is an excellent means for removing finest particles and suspensa from an effluent stream. It is most effective, has a small footprint and operates at very low costs. These characteristics make the dead-end Ultrafiltration the ideal pre-treatment for a Nanofiltration or a Reverse Osmosis. Thereby, the filtration units can be built at low costs using spiral-wound membrane modules. Additional benefits are the reduced operation costs of the filtration units and their enhanced performance.

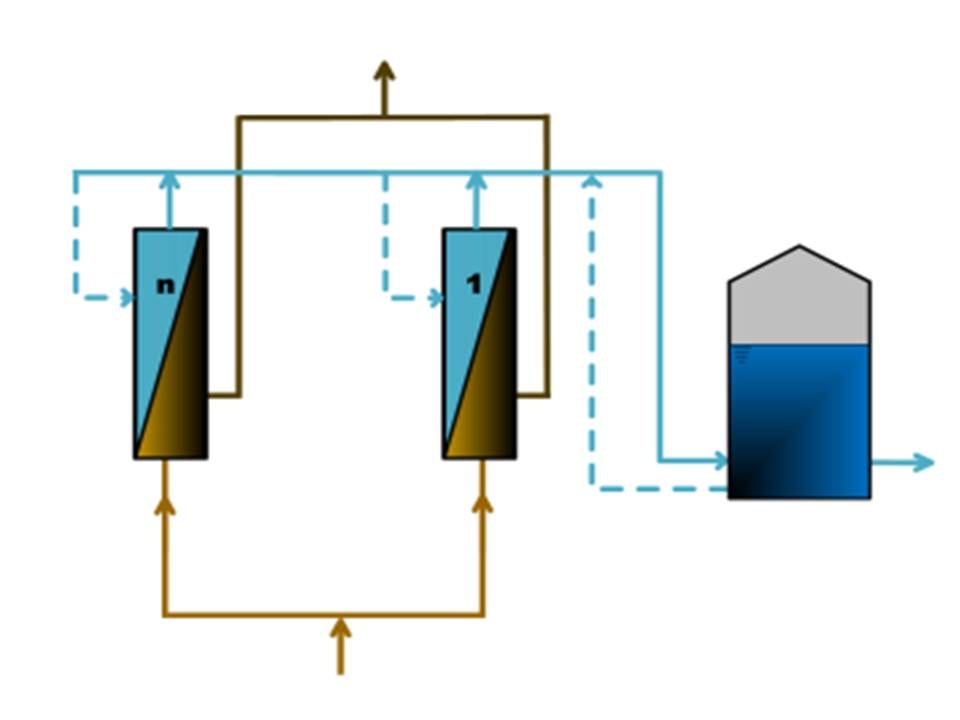

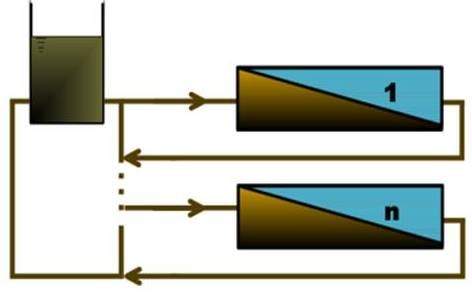

Ultrafiltration (side-stream cross-flow type)

The ultrafiltration of a BIOMEMBRAT®-type MBR uses external membranes and is placed on skids beside the reactors.

This has the decisive advantages of

having a very small footprint

being easily extendable & upgrade

service and maintenance being very easy

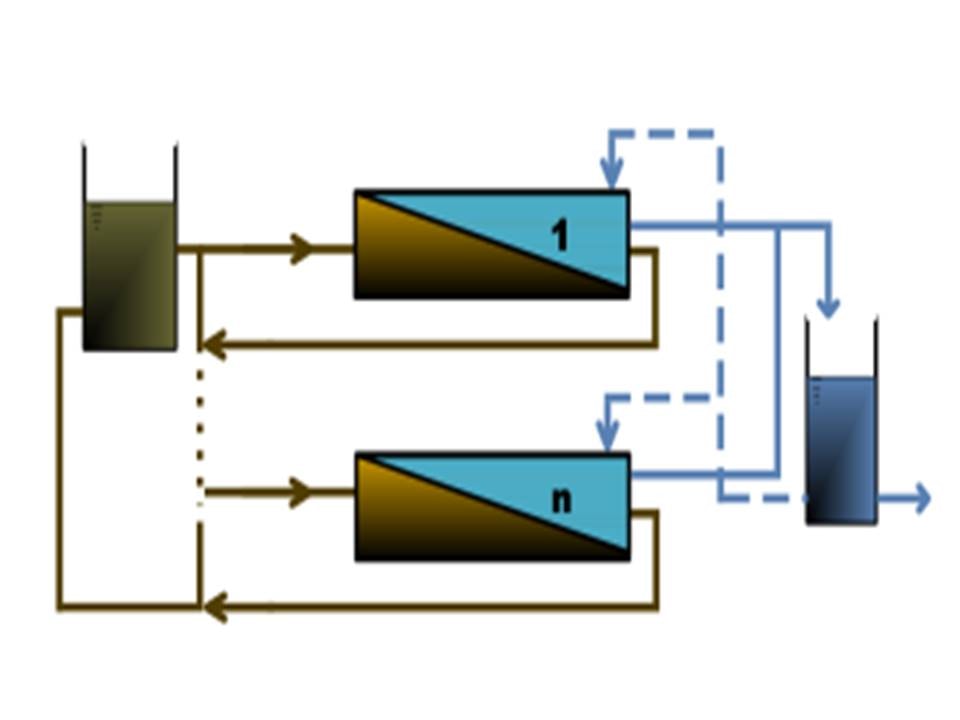

Ultrafiltration-LE (low energy type)

Any ultrafiltration of a BIOMEMBRAT®-type MBR uses external membranes and is placed on skids beside the reactors.

This has the decisive advantages of

having a very small footprint

being easily extendable & upgradable

service and maintenance are very easy.

The Ultrafiltration-LE has all the above listed advantages of a WEHRLE Ultrafiltration and has the additional advantage of saving 30-50 % of the energy uptake in the UF. To achieve this, new process steps have been added to the Ultrafiltration which enable the control of the boundary layer on the membrane surface and with it the flux over the membrane at reduced speed velocity in the UF modules.

|

Criteria |

BIOMEMBRAT® |

BIOMEMBRAT®-LE |

Conventional (submerged) membranes |

|

Energy consumption |

high |

low |

low |

|

Energy dynamic *) |

none |

flexibly adapts to the respective loads |

none |

|

Consumption of chemicals |

low |

high |

high |

|

Membrane lifetime |

high |

low |

low |

|

Manpower |

very little |

little |

high |

|

Cleaning process |

very simple |

simple |

complex |

|

Robustness |

very high |

high |

very low |

|

Flux (l/h*m²) |

very high |

high |

very low |

|

Throughput dynamic |

medium |

medium to high |

none |

|

Necessary surface for construction |

small |

medium |

large |

|

Investment costs |

low |

high |

high |

*) to save energy in case of less throughput

Within the range of the two above-mentioned processes, cross-flow and low-energy, WEHRLE offers tailor-made solutions for your task including dynamic energy consumption, i.e. your plant automatically adapts to throughputs < 100 %. Due to our experience gained from the construction of over 200 MBR plants, we are capable of developing solutions combining the advantages of both processes: guaranteeing high flux while at the same time saving energy and without having to use complex backflush systems.

Your advantages:

space-saving plants

simple extension & upgrade – flexibility and sustainability

energy dynamic: a sophisticated control system reduces the energy consumption in case of less throughput

simple upgrade of existing conventional biologies to MBRs